Installation requirements for Rotameter

Time: 2020-02-20 05:02:57 Click:0

Installation requirements for Rotameter is following:

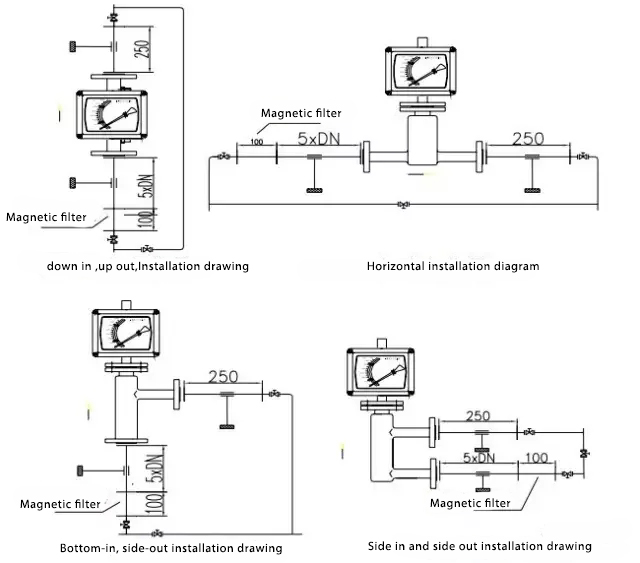

1. Instrument installation direction

Most of the rotor flowmeters must be installed vertically on a non-vibrating pipe. There should be no significant tilt. The angle between the centerline of the rotor flowmeter and the plumb line generally does not exceed 5 degrees. If theta; = 12 deg;, there will be 1% additional error. There is no strict requirement for the length of the upstream straight pipe section, but there are also manufacturers that require (2-5) D length, which is actually not necessary.

2.For the installation of dirty fluids

A filter should be installed upstream of the meter. When magnetically coupled metal tube rotor flow meters are used for fluids that may contain magnetic impurities, a magnetic filter should be installed in front of the meter. To keep the float and cone tube clean, especially for small-caliber instruments, the cleanliness of the float significantly affects the measured value.

3.The installation of the extended range of the rotor flowmeter

If the measurement requires a wide range of flow, when the range exceeds 10, you can put two floats of different shapes and weights in one meter, take a light float reading when the flow is small, and take a heavy float reading after the float reaches the top. Can be expanded to 50-100.

4.Installation of pulsating flow of rotor flowmeter

The pulsation of the flow itself, if there is a reciprocating pump or regulating valve upstream of the position where the instrument is to be installed, or there is a large load change downstream, etc., the measurement position should be changed or the pipeline system should be remedied, such as installing a buffer tank; If the gas pressure is too low during measurement, the upstream valve of the instrument is not fully open, and the regulating valve is not installed downstream of the instrument, etc., it should be improved by targeted measures, or a meter with a damping device should be selected instead.

5. The rotor flowmeter should exhaust the gas in the instrument for liquid

Angle type metal rotor flowmeter with inlet and outlet not in a straight line, pay attention to whether there is air remaining in the extension sleeve of the external transmission float when it is used for liquid, it must be exhausted; if the liquid contains small bubbles, it is easy to accumulate in the sleeve, and it should be discharged regularly. gas. This point is more important for small-caliber instruments, otherwise it will significantly affect the flow indication.

6. Rotor flowmeter flow value should be converted as necessary

If the meter is not specially ordered to the rotor flow meter manufacturer according to the medium parameters such as the density and viscosity, the liquid meter is usually calibrated with water and the gas meter is calibrated with air. The setting value is in the engineering standard state. When the fluid density, gas pressure and temperature of the operating conditions are inconsistent with the calibration, necessary conversion must be done. Conversion formulas and methods are detailed in the operating instructions of the manufacturer of the rotor flowmeter.

Article from:yibiaohui

Theroter flowmeteris one of the main products of the NOIKE. For more information, please visit the product page orZANKEstaff.