Installation requirements for electromagnetic flowmeters

Time: 2020-02-20 12:02:22 Click:0

1. The electromagnetic

flowmeter adopts flange connection, which is connected in the pipeline. The inner diameter of the sealing gasket should be slightly larger than the inner diameter of the pipeline to ensure the steady flow of pipeline fluid.

2. Avoid direct sunlight or places where the surrounding temperature is too high to prevent the insulation coil from being damaged due to excessive temperature rise in the excitation coil due to excessive temperature.

3. The electromagnetic flowmeter should be kept away from strong magnetic field equipment such as large motors, large transformers and electric welding machines. Shanghai Cozuo Instruments manufactures and processes density meters, transmitters, repairs domestic / imported transmitters, professional OEM processing, and Foxconn Cozuo meters in the instrument industry.

4. Try to stay away from places with corrosive air of ammonia and acid mist. If the on-site environmental conditions cannot be met, the user can ask when ordering, and the company will try to solve it.

5. The pipeline section where the electromagnetic flowmeter is installed should not have a large leakage current, and there should be a good grounding nearby.

6. The direction of fluid flow should be consistent with the flowmeter mark.

7. The installed pipeline must ensure that the measuring pipeline is always filled with the measured medium to prevent empty pipes.

8. Do not install the electromagnetic flowmeter on the pipeline section with negative pressure to prevent the lining material from falling off.

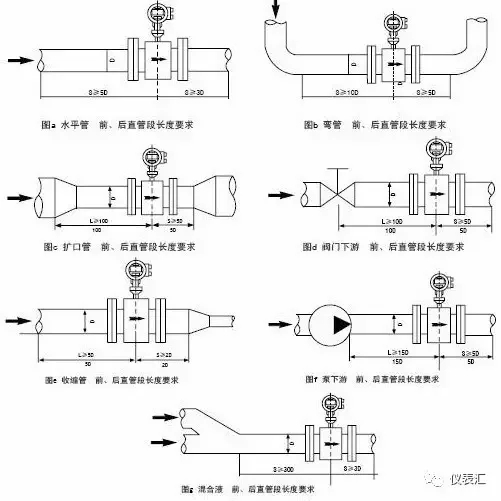

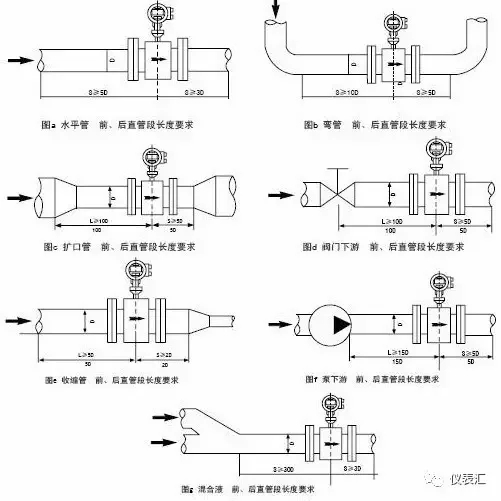

9. The upstream side of the

electromagnetic flowmeter should have a straight pipe section of not less than 5D times the pipe diameter.

Electromagnetic flowmeter WSC-100

10. There should be no less than 3 times the inner diameter of the pipe on the downstream side.

11. If there is a non-full-open gate valve or regulating valve upstream, the length of the straight pipe section upstream of the flow meter should be increased to a distance of 10 times the inner diameter of the pipeline.

12. The flow meter should usually be installed in a horizontal position, and the connection between the two electrodes should be on the same horizontal plane.

13. In order to prevent negative pressure, the elevation of the flow meter should be slightly lower than the elevation of the pipeline, or a certain head pressure must be guaranteed on the downstream side of the flow meter.

14. The inner diameter measured by the electromagnetic flowmeter should be consistent with the inner diameter of the pipeline. If the inner diameter cannot be the same, the inner diameter of the pipeline should be larger than the inner diameter of the flowmeter, and a tapered or expanded tube with a cone angle of not more than 15 should be installed between them.

15. When the electromagnetic flowmeter is installed obliquely or vertically, the flow direction should be from top to bottom.

16. For pipelines that do not allow flow interruption in the process, a bypass pipe and cleaning should be installed when the flowmeter is installed. This device ensures the continuous operation of the equipment system when the flowmeter is withdrawn.

17. It is forbidden to use a pipe rod or a rope to carry and hoist the measuring tube to avoid damage to the lining.

Electromagnetic flowmeter Installation diagram

Article from:yibiaohui

Theelectromagnetic flowmeteris one of the main products of the NOIKE. For more information, please visit the product page orZANKE staff.